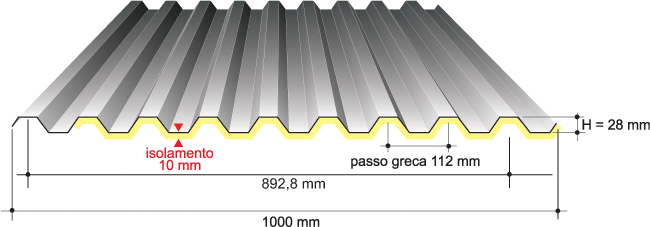

ISOGREK H28

ISOGREK h 28 is a single-sheet metal panel obtained by coupling a resistant metal profile h 28 mm to a layer of high-density polyurethane foamed continuously. Being modular, light, insulated and resistant, it adapts itself to any type of use for the plugging of the external building envelope.

Materials and quality:

ISOGREK h 28 is realized through a continuous production process, through the use of highly innovative technologies that allow to have a density of polyurethane superior to a simple single sheet panel. This feature, combined with the 9 waves trapezoidal geometry of the section, makes the product highly resistant to concentrated loads.

Reduced condensation effect:

ISOGREK h 28 is a panel that is impermeable to air and vapor, according to the European standard EN 14509. The humid air condenses on cold surfaces, therefore the polyurethane makes the support thermally insulated and avoids the formation of water on the inside of the panel.

Thermal and acoustic insulation:

ISOGREK h 28 has all the features and advantages of a simple corrugated metal sheet: (lightness, modularity, versatility and low costs) but also offers discrete thermal insulation and considerable noise reduction due to rain.

Dimensions

width mm 1000

length upon request from continuous production process.

Thicknesses (S)

mm 10

External support

galvanized steel, galvanized prepainted or plastified steel; stainless steel; natural or prepainted aluminium.

Insulation through continuous foaming process

polyurethane resins (PUR) - density 60 ±2 Kg/m³

Protective treatments for external support available

On request for external polyester coating, atoxic prepainted for food contact, silicone polyester, PVDF, thermoplastic Class A application of PVC plastic films or other films.

LOADS TABLE

PITCH BETWEEN SUPP.(m)

PANEL TICKNESS(mm)

SHEET TICKNESS(mm)

MATERIAL

| MAXIMUM UNIFORMLY DISTRIBUTED LOAD (daN/m2) - DEFLECTION * |

|---|

Panel

Thickness

(mm) | Material | Sheet

thickness

(mm) | Pitch 'L' in meters between the supports |

|---|

|

| 0,80 |

1,00 |

1,20 |

1,25 |

1,40 |

1,50 |

1,60 |

1,75 |

1,80 |

2,00 |

2,25 |

2,50 |

2,75 |

3,00 |

|---|

| 10 | ALLUMINIO | 0,5 |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

| 10 | ALLUMINIO | 0,6 |

579 |

405 |

235 |

— |

148 |

— |

99 |

— |

69 |

52 |

— |

— |

— |

— |

| 10 | ALLUMINIO | 0,7 |

753 |

473 |

274 |

— |

172 |

— |

115 |

— |

81 |

63 |

— |

— |

— |

— |

| 10 | ALLUMINIO | 0,8 |

943 |

542 |

313 |

— |

197 |

— |

132 |

— |

93 |

75 |

— |

— |

— |

— |

| 10 | ALLUMINIO | 1,0 |

1245 |

677 |

392 |

— |

247 |

— |

165 |

— |

115 |

89 |

— |

— |

— |

— |

| 10 | ACCIAIO | 0,5 |

— |

1011 |

— |

517 |

— |

300 |

— |

189 |

— |

126 |

89 |

64 |

49 |

37 |

| 10 | ACCIAIO | 0,6 |

— |

1214 |

— |

621 |

— |

359 |

— |

226 |

— |

151 |

106 |

77 |

58 |

45 |

| 10 | ACCIAIO | 0,7 |

— |

1418 |

— |

725 |

— |

419 |

— |

264 |

— |

177 |

124 |

91 |

68 |

52 |

| 10 | ACCIAIO | 0,8 |

— |

1620 |

— |

829 |

— |

480 |

— |

301 |

— |

202 |

142 |

103 |

77 |

59 |

| 10 | ACCIAIO | 1,0 |

— |

2026 |

— |

1037 |

— |

600 |

— |

378 |

— |

252 |

177 |

129 |

97 |

74 |