ISODECK 3G

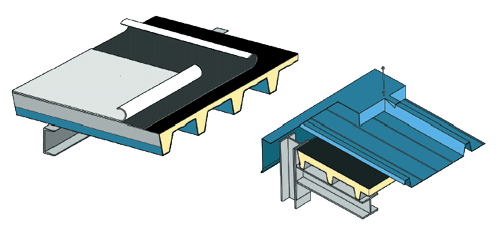

DECK roofs are produced in continuous with a galvanized steel metal support and a waterproofed felt-paper substrate support on which the different waterproofing sheaths and layers can be applied to protect the cover.

The advanced profile of the DECK cover has been totally designed by the Research and Development Division.

Dimensions

width mm 1000

length upon request from continuous production process.

Thicknesses (S)

mm 40 - 50 panels of non standard thicknesses can be supplied upon request previous agreement on minimum quantities.

External support

galvanized steel, galvanized prepainted or plastified steel; stainless steel; natural or prepainted aluminium.

Flexible support

brown felt bituminous paperboard. Due to its properties (hot binder, waterproof and insulating) the bitumen is widely used in roofing.

Insulation through continuous foaming process

Polyurethane resins (PUR) and (not standard) polyisocianurate foams (PIR), density 39 ±2 Kg/m³ Declared value of thermal transmittance for a panel after 25 years of its installation, (Appendix C - EN 13165) Initial value of thermal conductivity: λ = 0.020 W/(mK)

Protective treatments for external support available

On request for external polyester coating, atoxic prepainted for food contact, silicone polyester, PVDF, thermoplastic Class A application of PVC plastic films or other films.

LOADS TABLE

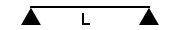

PITCH BETWEEN SUPP.(m)

PANEL TICKNESS(mm)

SHEET TICKNESS(mm)

MATERIAL

| MAXIMUM UNIFORMLY DISTRIBUTED LOAD (daN/m2) - DEFLECTION * |

|---|

Panel

Thickness

(mm) | Material | Sheet

thickness

(mm) | Pitch 'L' in meters between the supports |

|---|

|

| 1,00 |

1,25 |

1,50 |

1,75 |

2,00 |

2,25 |

2,50 |

|---|

| 40 | ACCIAIO | 0,5 |

246 |

158 |

110 |

80 |

62 |

48 |

— |

| 40 | ACCIAIO | 0,6 |

295 |

190 |

132 |

96 |

74 |

58 |

— |

| 40 | ACCIAIO | 0,8 |

393 |

253 |

176 |

128 |

99 |

77 |

— |

| 40 | ACCIAIO | 1,0 |

491 |

316 |

220 |

160 |

124 |

96 |

— |

| 50 | ACCIAIO | 0,5 |

246 |

158 |

110 |

80 |

62 |

48 |

— |

| 50 | ACCIAIO | 0,6 |

295 |

190 |

132 |

96 |

74 |

58 |

— |

| 50 | ACCIAIO | 0,8 |

393 |

253 |

176 |

128 |

99 |

77 |

— |

| 50 | ACCIAIO | 1,0 |

491 |

316 |

220 |

160 |

124 |

96 |

— |

| MAXIMUM UNIFORMLY DISTRIBUTED LOAD (daN/m2) - DEFLECTION * |

|---|

Panel

Thickness

(mm) | Material | Sheet

thickness

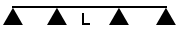

(mm) | Pitch 'L' in meters between the supports |

|---|

|

| 1,00 |

1,25 |

1,50 |

1,75 |

2,00 |

2,25 |

2,50 |

|---|

| 40 | ACCIAIO | 0,5 | 308 | 197 | 137 | 100 | 77 | 60 | 49 |

| 40 | ACCIAIO | 0,6 | 369 | 237 | 165 | 120 | 92 | 72 | 59 |

| 40 | ACCIAIO | 0,8 | 491 | 316 | 220 | 160 | 124 | 96 | 79 |

| 40 | ACCIAIO | 1,0 | 614 | 395 | 275 | 200 | 155 | 120 | 99 |

| 50 | ACCIAIO | 0,5 | 308 | 197 | 137 | 100 | 77 | 60 | 49 |

| 50 | ACCIAIO | 0,6 | 369 | 237 | 165 | 120 | 92 | 72 | 59 |

| 50 | ACCIAIO | 0,8 | 491 | 316 | 220 | 160 | 124 | 96 | 79 |

| 50 | ACCIAIO | 1,0 | 614 | 395 | 275 | 200 | 155 | 120 | 99 |