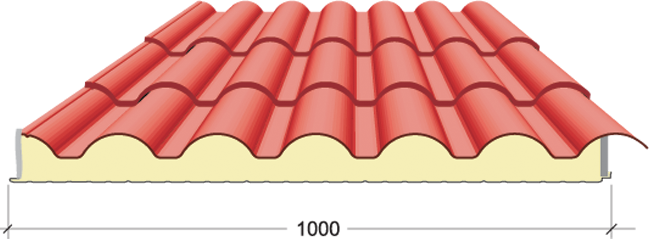

ISOMETAL SUPERCOPPO

Specifically designed to create roofs of buildings of historical and architectural interest, it increases the value of the building by creating a prestigious aesthetic effect that faithfully reproduces the shape of the brick roofing.

SUPERCOPPO is the first panel that imitates the shape of traditional brick roofing actually produced with a continuous cycle.

SUPERCOPPO guarantees considerable savings without sacrificing the aesthetics of a brick roof, offering further benefits, including: reducing the weight of the roof, in this way the underlying structures are not overloaded, making it the ideal material for interventions rehabilitation and restructuring; the laying time is reduced compared to the traditional system with brick tiles, with lower installation costs and increased productivity; ordinary maintenance interventions are reduced to a minimum respect to the problems that may arise with a traditional covering in roof tiles during the winter season; elimination of problems due to birds and insects in the attic.

Dimensions

width mm 1000

length upon request from continuous production process.

Thicknesses (S)

mm 40 - 60 - 80 - 100

Tile height

mm 40

External support

galvanized steel, galvanized prepainted or plastified steel; stainless steel.

Flexible support

cylindrical bituminous felt paper; embossed aluminum 0.08 mm thick; fiberglass.

Insulation through continuous foaming process

Polyurethane resins (PUR) and (not standard) polyisocianurate foams (PIR), density 39 ±2 Kg/m³ Declared value of thermal transmittance for a panel after 25 years of its installation, (Appendix C - EN 13165) Initial value of thermal conductivity: λ = 0.020 W/(mK)

LOADS TABLE

PITCH BETWEEN SUPP.(m)

PANEL TICKNESS(mm)

SHEET TICKNESS(mm)

MATERIAL

| MAXIMUM UNIFORMLY DISTRIBUTED LOAD (daN/m2) - DEFLECTION * |

|---|

Panel

Thickness

(mm) | Material | Sheet

thickness

(mm) | Pitch 'L' in meters between the supports |

|---|

|

| 1,05 |

1,40 |

1,75 |

2,10 |

2,45 |

2,80 |

3,15 |

3,50 |

|---|

| 40 | ACCIAIO | 0,5 + 0,4 |

417 |

283 |

170 |

125 |

95 |

75 |

65 |

48 |

| 60 | ACCIAIO | 0,5 + 0,4 |

530 |

365 |

255 |

195 |

154 |

120 |

93 |

84 |

| 80 | ACCIAIO | 0,5 + 0,4 |

590 |

442 |

333 |

278 |

192 |

155 |

97 |

78 |

| 100 | ACCIAIO | 0,5 + 0,4 |

610 |

470 |

385 |

305 |

210 |

176 |

123 |

98 |

| MAXIMUM UNIFORMLY DISTRIBUTED LOAD (daN/m2) - DEFLECTION * |

|---|

Panel

Thickness

(mm) | Material | Sheet

thickness

(mm) | Pitch 'L' in meters between the supports |

|---|

|

| 1,05 |

1,40 |

1,75 |

2,10 |

2,45 |

2,80 |

3,15 |

3,50 |

|---|

| 40 | ACCIAIO | 0,5 + 0,4 | 423 | 291 | 178 | 133 | 108 | 84 | 72 | 53 |

| 60 | ACCIAIO | 0,5 + 0,4 | 544 | 386 | 267 | 205 | 167 | 144 | 105 | 96 |

| 80 | ACCIAIO | 0,5 + 0,4 | 605 | 463 | 366 | 294 | 203 | 174 | 112 | 100 |

| 100 | ACCIAIO | 0,5 + 0,4 | 622 | 483 | 397 | 322 | 226 | 189 | 136 | 123 |